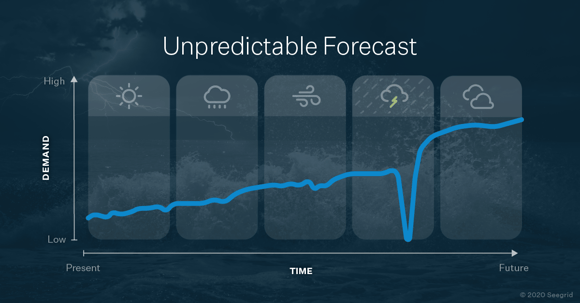

To say 2020 was a year like no other is an understatement. The global pandemic changed the way we live, from how we work to how we shop, and everything in between. In the consumer goods space, the pandemic rewrote the script for forecasting demand.

Historically, demand in this space has been easy to predict. It’s typical to see seasonal spikes around the holidays, for example, as well as the back-to-school timeframe and tax season. This demand was expected, and companies had ample time to prepare their supply chains, hire seasonal labor, and do it all in an organized and safe way.

With the arrival of COVID-19 in early 2020, that predictability vanished. As the population went into lockdown and life became more centered around the home, demand for certain goods began to spike. At the same time, growing case numbers coupled with shutdowns and other restrictions aimed at slowing the spread exacerbated the existing labor shortage. Finally, the need to meet increased demand with fewer workers while adhering to new regulations around social distance and cleanliness increased safety pressure, with manufacturers now focused not only on managing an accident-free facility, but also on reducing operator touches. The result was the perfect storm of surging demand, labor shortages, and an increased focus on health and safety.

The once predictable cycles for consumer goods are now a thing of the past, and forecasting demand and labor needs has become a trickier proposition. It could be some time before the storm clouds of the pandemic give way to clearer skies and a more predictable pattern. Realistically, we may never return to pre-pandemic cycles. Achieving success in the future of the space requires an increased focus on flexibility and scalability to address unpredictable demand and labor, as well as a continued dedication to safety across the board.

Using Automation Technology to Manage Demand

Automated material movement has been helping to meet demand and solve both workforce management and employee availability challenges for years. In the new consumer goods landscape, automation solutions will take an even more critical role in helping manage unpredictable peaks and valleys. Now more than ever, supply chains must have the flexibility and scalability to ramp up quickly, change processes easily, and redeploy to different operations when needed. Automation enables these changes seamlessly, in a manner that ensures consistency.

Addressing Labor Shortages and Workforce Safety with AMRs

Finding and retaining manufacturing personnel has become increasingly challenging in recent years, and new restrictions put in place to curb the spread of COVID-19 have only complicated matters further. Autonomous mobile robots (AMRs) help ease the strain of labor shortages. With no training or ramp-up required, AMRs complement the role of human workers by taking over many monotonous, repetitive actions and allowing employees to focus on more high-value, cognitive tasks. Hiring temporary workers to address demand spikes – seasonal or otherwise – is expensive and increases risk as more variables are introduced into the facility. Automation offers a more cost effective, predictable, and safer solution, both in terms of error and accident reduction and maintaining enhanced hygiene and physical distancing.

Without question, the events of 2020 have changed demand forecasting for the consumer goods space, perhaps permanently. Yes, the perfect storm brought by COVID-19 will eventually pass, giving way to bluer skies and perhaps a more predictable forecast for a time, but we must always be ready for the next storm. The lesson we must take from this challenging period is that managing the supply chains of the future – in the consumer goods space and beyond – requires the utmost flexibility and agility to address quickly changing demand and labor scenarios, in a manner that ensures employees’ health and safety. There is significant opportunity for growth and profitability in the future. Automated solutions can help you respond to whatever storms may come in a way that increases productivity, ensures safety, reduces labor costs, and delivers strong ROI.

Download our infographic to learn more about leveraging AMRs to address demand, labor, and safety challenges.